There are several key reasons why pipe relining may fail:

- Pre-existing blockages or obstructions: Any materials stuck in the pipe, such as sediment, grease buildup, wet wipes, or tree roots, can stop the epoxy resin from properly adhering to the original pipe walls.

- Incorrect pipe material or environment: The resin must be compatible with both the type of pipe and its environment. Using the wrong formulation for specific pipe materials or conditions can lead to bonding issues.

- Failure to clear root intrusion: If root masses inside the pipe are not fully removed before inserting the epoxy liner, gaps may form between the resin and the pipe wall.

- Poor workmanship: Inadequate preparation of the inner walls or insufficient saturation of the liner with resin can prevent proper bonding.

It is crucial to swiftly identify these complications in your sewer line, especially if you aim to repair the drain without disturbing your garden or driveway. Drain Fixers Pipe Relining achieves this through a thorough CCTV pipe inspection. With proper assessment, we can evaluate the pipe’s condition, select the appropriate relining materials, and address issues such as blockages or tree roots before beginning the relining process.

In many cases, relining can be attempted again after accurately diagnosing and rectifying the reasons for the initial failure.

A complete pipe replacement may be necessary if the relining fails and problems persist.

Identifying Problems with Failed Pipe Relining

When a sewer pipe relining fails, various diagnostic methods can help identify the issue:

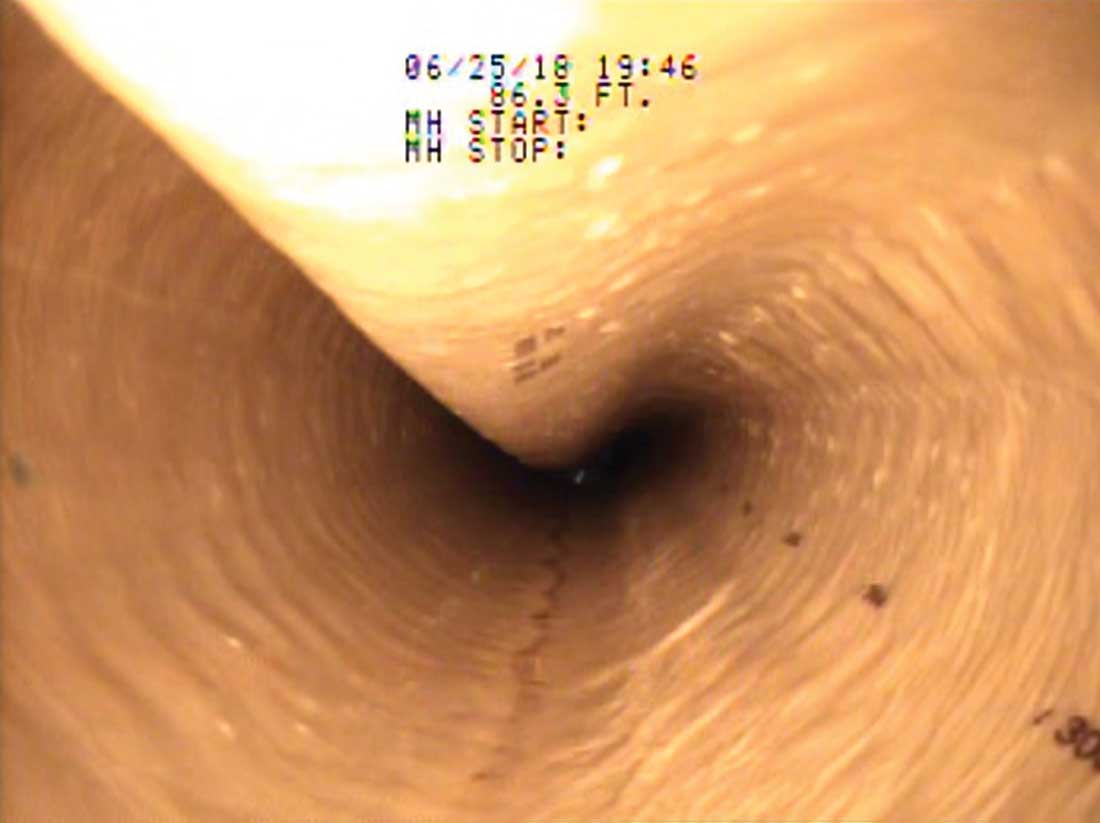

- Perform a CCTV Pipe Inspection: Utilizing a high-quality CCTV camera allows for a thorough visual examination without excavating the garden. This diagnostic step effectively identifies and helps resolve blockages or root intrusions.

- Monitor for Recurring Drain Issues: If problems such as significant plumbing leaks or persistent water leaks continue, it may indicate that attempts to reline broken pipe sections were unsuccessful.

- Assess Resin Saturation and Curing: Check whether enough resin was applied and whether it was allowed to cure properly throughout the entire length of the pipe.

- Review Original Pipe Conditions: Were underlying issues addressed before relining? Were there any obstructions or incompatible pipe materials?

It is crucial to quickly identify the factors that led to the relining issue, especially if pipeline damage is suspected. We can then reconsider the relining options with proper preparations or explore alternative repair methods if relining is unsuitable.

Are you encountering issues after relining? Contact Drain Fixers Pipe Relining for a second opinion. Our skilled team excels at diagnosing and resolving problems to ensure a permanent relining repair.

Who is responsible for Premature Relining Failure

Determining responsibility for a prematurely failing relined pipe can be challenging. As a consumer, it is essential to ensure that the contractor provides a workmanship guarantee and product warranty to cover potential defects.

The best plumbing companies usually offer a product warranty period of 10 to 15 years after completion. If leaks or blockages arise during this warranty period—indicating possible liner separation—the contractor should perform repairs at no additional cost.

To assess liability for premature failure, review how thoroughly the pipe relining addressed the issue:

- Original Pipe Condition: Were underlying problems fully addressed beforehand?

- Installation Practices: Was the process conducted according to industry standards?

- Liner Materials and Compatibility: Were the proper resin and liner combinations used for your specific pipe type and environment?

At Drain Fixers Pipe Relining, we are committed to repairing your sewer pipes effectively and reliably. All our pipe relining services come with a 50-year product warranty. We utilize only high-quality epoxy resins that are suitable for your pipelines. Our team of experienced and insured technicians strictly follows all proper protocols for pipe relining solutions.

If we fall short of your expectations, we will resolve your relining issues at no extra cost.

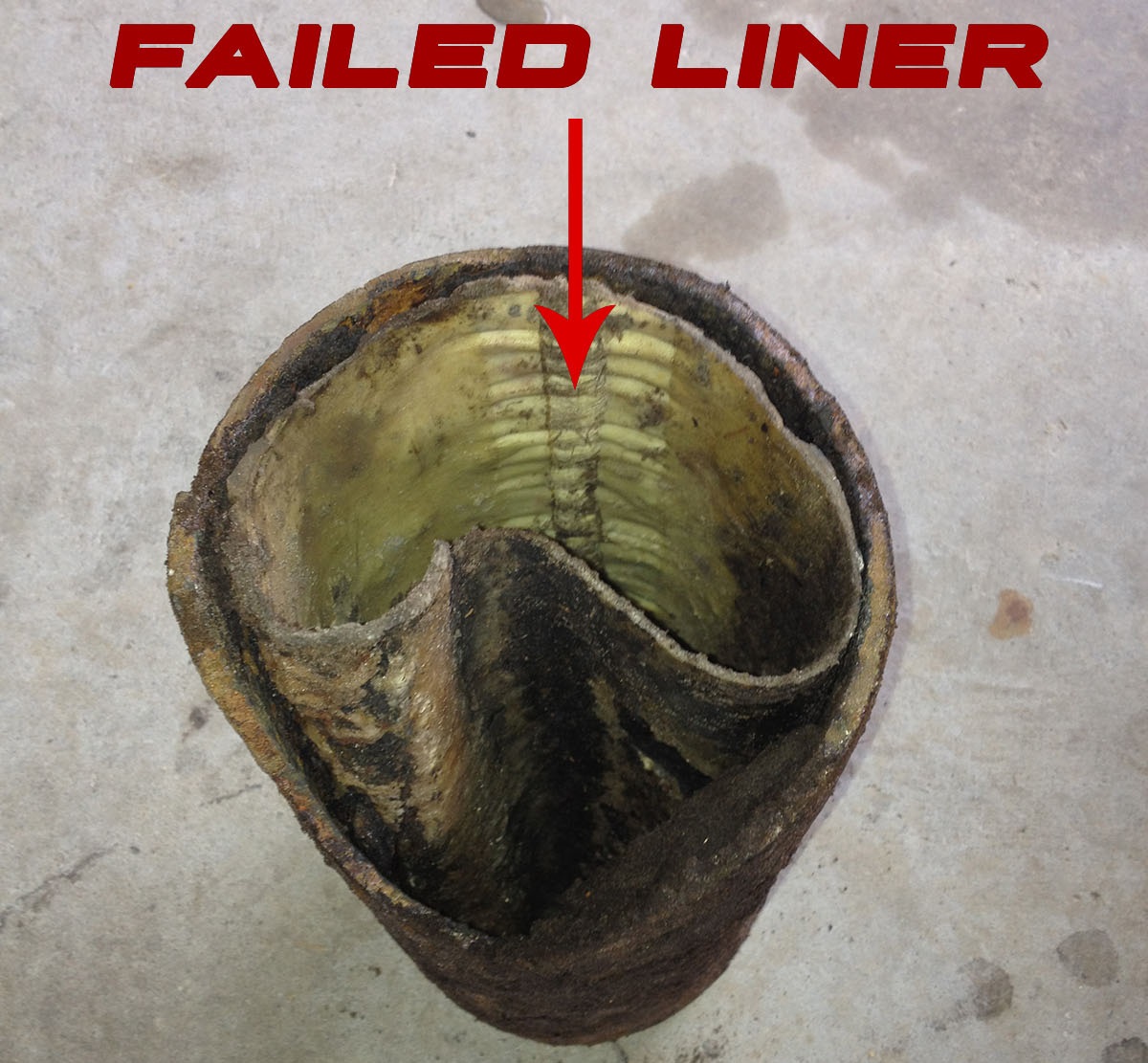

Visible Signs Your Pipe Relining Repair Has Failed

If a relining repair fails, visible signs may appear within the property. These signs include:

- Leaks: Watermarks or dampness on walls and floors can indicate leakage.

- Persistent blockages: Slow drainage over time may indicate that the liner has detached from the pipe walls.

- Sewage backflow: If your sewer pipes emit gases or waste through household fixtures, this could indicate a malfunctioning liner.

- Ground subsidence: Soil sinking near the pipe location could signify a collapsed liner.

Identifying these problems quickly is essential for preventing further damage. If you notice any troubling symptoms following a relining procedure, do not hesitate to contact our office for a swift resolution. We can urgently inspect, diagnose, and rectify liner failures versus pipe replacements before the issues worsen.

Options for Fixing a Failed Relining Repair

If a pipe relining repair fails, there are still options to fix the issue without a full pipe replacement:

- Redo the relining: With proper preparation and use of experienced relining technicians, the damaged pipe can undergo the no-dig process again. Different epoxy resin or liner combinations may need to be used.

- Patch isolated failure spots: If the failure in your drain is contained to a single section, patches may be suitable to repair small, affected areas.

- Partial pipe replacement: A tailored approach is crucial; replacing only a severely damaged section of the pipe and confirming that relining can be executed on viable sections may be appropriate.

- Full pipe replacement: If relining is no longer feasible, replacing an entire pipe is a last resort.

We can promptly mobilize our skilled team to evaluate your faulty drain repair and scrutinize the initial relining attempt to determine the best course of action. This ensures that problems are fixed properly the first time without unnecessary pipe replacement.

Repeating the Relining Process Correctly

If an initial pipe relining repair fails, it is essential to repeat the process correctly to prevent ongoing blockages and future deterioration. A proper outcome requires comprehensive pipeline preparation, including clearing blockages or tree roots before technicians arrive to perform the relining.

Using CCTV footage, Drain Fixers Pipe Relining can inspect the affected sections and remove debris, facilitating effective adhesion of the resin. This inspection also allows us to assess what may have caused the initial relining failure, whether due to incorrect materials, poor workmanship, or underlying issues.

Selecting the appropriate resin is crucial for withstanding wear and tear. This process involves scrutinizing compatibility details and analysing materials for their absorption efficiencies. During the application, it is important to adhere to stringent industry standards, ensuring that the pipe’s interior walls are thoroughly coated before the liner is allowed to cure completely.

At Drain Fixers Pipe Relining, our expert technicians take all necessary steps to ensure that any repaired relining work is completed to the highest professional standard. As the Victorian Building Authority requires, we guarantee our workmanship for 6 years and will promptly investigate and rectify any issues that arise. We also provide a 50-year product warranty on completion.

Please contact our office at 1300 663 569 to have your sewer pipes assessed and relined properly and effectively.

Section Pipe Relining Repairs for Isolated Problem Areas

If a pipe relining repair fails in a small, contained area, pipe patching may be a suitable solution that avoids the need to reline the entire system. Pipe patching involves inserting a resin-saturated liner into the isolated failure spot within the drain to address issues such as holes, gaps, or cracks in the existing liner.

Pipe patching is ideal for minor repairs for defects less than five metres in length. It works well for problems like pinholes, small cracks, joint failures, or areas where the liner has slightly detached from the wall. This method reinforces weakened pipe sections, helping preserve the integrity of relined pipes and prevent further significant failures.

The patching process involves inserting a trimmed liner section coated with epoxy resin into the damaged area through access points. Once the liner is saturated and cured, it forms a tight seal, restoring the pipe’s integrity and maintaining the effectiveness of the previous relining work without requiring major interventions.

Repeating the full pipe relining may be a better option for larger repair areas exceeding five metres. However, pipe patching is generally more cost-effective and less disruptive for concentrated issues under five metres than other methods.

Partial or Complete Pipe Replacement

Unlike trenchless pipe relining, traditional methods require excavation to remove compromised piping sections.

Factors that may favour pipe replacement include:

- More than 50% of the piping system is too damaged for relining.

- The failed liner has either collapsed, filled with obstructions, or detached completely.

- The type of pipe is incompatible with reliable relining methods.

While replacement is more invasive, restoring adequate drainage and water flow is sometimes necessary. Although the repair may take longer, and access to your property may be temporarily restricted, the result is worth it.

At Drain Fixers Pipe Relining, our expert team works diligently to avoid unnecessary pipe replacement through accurate diagnostics and proper repair preparations. However, if replacement is deemed essential, we are committed to completing the job efficiently and with minimal disruption.

Avoiding Future Relining Failures

To avoid future relining failures, there are some key prevention tips to follow:

- When considering relining vs pipe replacement, properly prepare pipes before relining; employ CCTV inspections to discover and clear any hindrances.

- Choose appropriate epoxy resin and liner combinations compatible with your specific pipe type and environment.

- Follow proper installation techniques – Ensure complete saturation and curing times for resins.

- Use reputable contractors – Choose licensed, experienced and insured drainage technicians with a proven relining record.

- Conduct routine inspections – Annual inspections confirm the reline repair is still working properly and in good condition.

We recommend integrating preventive strategies to extend the lifespan of your relining repairs and maintain their long-term efficiency. To ensure the quality of your drains, it’s important to secure these services from trusted experts like Drain Fixers Pipe Relining.

If you have any post-service concerns, please don’t hesitate to contact our team at 1300 663 569. We’re here to help ensure the ongoing performance of your relined pipes.

Proper Installation Techniques

Proper installation processes must be followed for a pipe relining repair to last. Thorough cleaning with high-pressure water jets or mechanical augers removes all obstructions, such as roots, grease, and mineral build-up, before installing the epoxy liner.

Selecting the appropriate resin formulation compatible with the pipe material and the environment is essential for achieving optimal bonding. Ensuring no air pockets or gaps is important when the liner is vacuum-impregnated with resin, as this guarantees full saturation. Experts must carefully monitor saturation levels to determine the correct amount of resin needed based on the pipe’s size and condition, which is crucial for successful repairs.

Once prepared, the pipe’s access points are sealed properly to contain the lining material during the insertion and curing process. Ongoing monitoring is vital to ensure the thermoset resin remains in place long enough to cure completely.

Industry guidelines specify cure times based on surrounding temperatures and humidity. Companies like Drain Fixers Pipe Relining provide reliable and durable pipelining solutions by following strict procedures and employing skilled professionals.

For professional repairs done right the first time, contact our team at 1300 663 569.

Root Removal & Pipeline Preparation

Thorough root removal and general pipeline preparation are crucial before starting any pipe relining project. An experienced drainage technician will use drain cameras or video pipe inspections to perform a pipe reline survey, helping to locate intruding tree roots, cracks, missing pipe sections, or other forms of damage.

High-pressure jetting, combined with mechanical augers, is used to clear out roots, grease buildup, mineral deposits, and other obstructions along the entire pipeline length. The goal is to restore the piping as close as possible to its original smooth bore.

Once the passageway is clear, technicians will check the compatibility specifications and select the optimal grade of epoxy resin for relining the piping system. After sealing the access points, the liner is then saturated with resin to prepare for insertion.

It is essential to remove all debris and clear any obstructions. Thorough cleaning and preparation give the resin liner the best chance of adhering properly throughout the length of the pipeline during the curing process, which contributes to long-lasting pipe integrity after relining.

Selecting Quality Materials for Your Pipes

When choosing quality materials for pipe relining, the type of resin and liner must match your specific pipe layout. Pipe relining is not a “one brand fits all” approach. Different liners and resins are required for various scenarios. Some pipelines need strength, while others require flexibility or structural integrity. After thoroughly inspecting your drains, we carefully select the best liner and resin tailored to your specific needs to achieve a permanent repair solution. As a provider of high-quality service and materials, we exclusively use styrene-free, non-toxic resins. All relining products are Watermarked for use in accordance with Australian Plumbing Standards.

The method we use for the liner can vary depending on the site conditions. In the ongoing debate between pipe relining and traditional methods, we utilize felt, glass, or carbon fibre materials to reinforce the resin, customizing it to meet your system’s configuration and flow requirements. The proper liner textures help prevent binding while allowing for effective resin integration.

With decades of experience, our experienced team understands which specific relining components work best for long-term viability. We stand behind our workmanship with satisfaction guarantees against defects for many years after completion.